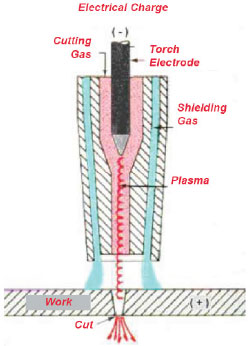

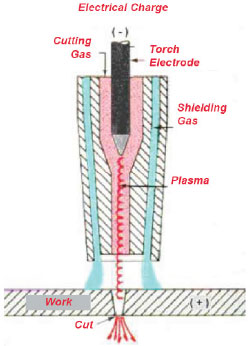

Plasma from the plasma cutter itself through the workpiece to be cut thus forming a finished circuit back.

Plasma cutting torch temperature.

Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma typical materials cut with a plasma torch include steel stainless steel aluminum brass and copper although other conductive metals may be cut as well plasma cutting is often used in fabrication shops automotive repair and restoration industrial construction and.

When used for cutting the plasma gas flow is increased so that the deeply penetrating plasma jet cuts through the material and molten material is removed in the efflux plasma.

For stacked metals plasma cutting proves to be more suitable than an oxy fuel system.

A typical value of temperature obtained in a plasma jet torch is on the order of 28000 c 50000 f compared to about 5500 c 10000 f in ordinary electric welding arc.

You can also cut some ferrous metals.

A flame cutting system or oxyfuel cutting torch is a practical choice for mild steel over 1 inch thick whereas a plasma torch is better and more efficient for thinner materials whether ferrous or non ferrous.

A plasma torch also known as a plasma arc plasma gun or plasma cutter plasmatron is a device for generating a directed flow of plasma.

What does the future hold for plasma cutting.

Just as oxy fuel torches can be used for either welding.

Unlike a cutting torch a plasma cutter doesn t use the oxidation process to cut through metal.

1 2 3 the plasma jet can be used for applications including plasma cutting plasma arc welding plasma spraying and plasma gasification for waste disposal.

A cutting torch head is used to cut materials.

The temperature of the plasma is in excess of 20 000 c and the velocity can approach the speed of sound.

It s unlikely anyone would want to use that heat to cut a metal plate but this shows the.

Although high end plasma cutters can chew through metal plates at a rate of 200 inches per minute with 40 000 f of heat some scientists have recorded plasma reaching close to 10 trillion degrees f.

Plasma cutting conductive gas with a temperature of up to 30 000 c makes plasma cutting so special.

When cutting the metal is first heated by the flame until it is cherry red.

The basic process in plasma cutting and welding is to create an electrical channel of superheated electrically ionised gas i e.

Ideal choices for this method include conductive and non ferrous metals like aluminum copper brass steel etc.

Once this temperature is attained oxygen is supplied to the heated parts by pressing the oxygen blast trigger.